唐山

![]()

开通时间:..

最后更新时间:..

博士、教授、博士生导师,入选”国家青年创新人才计划”,曾获”王仁先生青年科技奖”,一直致力于固体力学的前沿科学问题展开研究,尤其是复杂材料在不同尺度下的建模和计算及微观结构与宏观力学性能之间的关联,擅长本构建模,结合人工智能和数据驱动力学实现复杂材料和结构的设计,提出计算算法和编程去解决工程应用中的实际问题,并致力于自主CAE软件的开发。应邀参与撰写Springer出版社书章2篇,已发表论文101篇,其中SCI论文98篇,SCI他引1864次,谷歌学术引用2157次, 其中包括计算力学顶级期刊Computer Methods in Applied Mechanics and Engineering,Computational Mechanics,固体力学顶级期刊Journal of Mechanics and Physics of Solids;International Journal of Plasticity,International Journal of solids and Structures;结构材料顶级期刊Acta Materials;高分子材料顶级期刊Macromolecules, Soft Matter;Polymers;综合类期刊Advance Materials,Advance Energy Materials,Nano letter,Nanoscale 等。近5年发表第一或通讯作者论文39篇,谷歌学术引用1696次。

本组现有博士生11名,硕士生11名。已毕业博士生4名,硕士生8名。本组学术氛围浓厚,研究经费充足,欢迎具有力学、物理和材料背景的优秀研究生(硕士和博士)加入本组,也欢迎数学物理基础扎实的本科生来组内实习。

联系方式:

邮箱:shantang@dlut.edu.cn

电话:18723558261

教育和工作经历:

1996-09 至 2000-07 华中科技大学 学士

2000-09 至 2003-07 中科院力学所 硕士 导师:魏悦广 院士

2003-09 至 2008-07 新加坡国立大学 博士 导师:Li Cheng 教授

2009-09 至 2012-09 美国西北大学 博士后 合作导师: W. K. Liu 教授

2012-09 至 2017-03 重庆大学 教授 博导

2017-03 至 今 大连理工大学 教授 博导

学术专长:

大数据驱动力学,计算力学,断裂力学、材料本构和多尺度力学。具有扎实的数学功底和很强的计算机编程能力,擅长使用合适的计算力学工具来解决工程应用领域的难题。多年来致力于应用力学(连续介质力学、统计力学、热力学、数据驱动力学等),去解决工程应用中的断裂、破坏、结构设计和材料性能等问题,并致力于自主CAE软件的开发。

代表性研究项目:

1、国家级人才青年项目;

2、国家自然科学基金委员会面上项目:仿弹性蛋白高分子材料的粘弹性力学性能研究;

3、国家自然科学基金委员会面上项目:基于透射/扫描电镜原位实验的高熵合金跨尺度断裂破坏研究;

4、973计划课题:XXXX车身结构XXXX研究;

5、中船重工701所项目:XX舱室结构数字孪生模型构建技术研究;

6、华为机器有限公司委托开发项目:填缝胶点胶压合流体仿真。

近五年代表作:

[1] Zhang, Gang; Qiu, Hai; Tang, Shan*; Dan, Peng*; et al. (2022). Modeling Tunable Fracture in Hydrogel Shell Structures for Biomedical Applications. Gels.

[2] Liu, Daoping; Yang, Hang; Tang, Shan; Liu, Wing Kam; Guo, Xu; et al. (2022). Mechanistically informed data-driven modeling of cyclic plasticity via artificial neural networks. Computer Methods in Applied Mechanics and Engineering.

[3] Huang, Chuanyang; Gao, Bo; Zhou, Nian; Tang, Shan; et al. (2022). Enabling High-fidelity Twin Pattern Prediction in Polycrystals—A Mesoscale Grain Boundary Plasticity Model. International Journal of Plasticity.

[4] Du, Zongliang, Zhang, Gang, Guo, Tianfu, Tang, Shan*; et al (2020). Tension-compression asymmetry at finite strains: A theoretical model and exact solutions. Journal of the Mechanics and Physics of Solids.

[5] Tang, Shan; et al. (2019). MAP123: A data-driven approach to use 1D data for 3D nonlinear elastic materials modeling. Computer Methods in Applied Mechanics and Engineering.

[6] Zhang, Gang; Guo, Tian Fu; Guo, Xu; Tang, Shan*; et al. (2019). Fracture in tension-compression-asymmetry solids via phase field modeling. Computer Methods in Applied Mechanics and Engineering.

[7] Yang, Hang; Guo, Xu; Tang, Shan*; et al (2019). Derivation of heterogeneous material laws via data-driven principal component expansions. Computational Mechanics.

代表性成果简介:

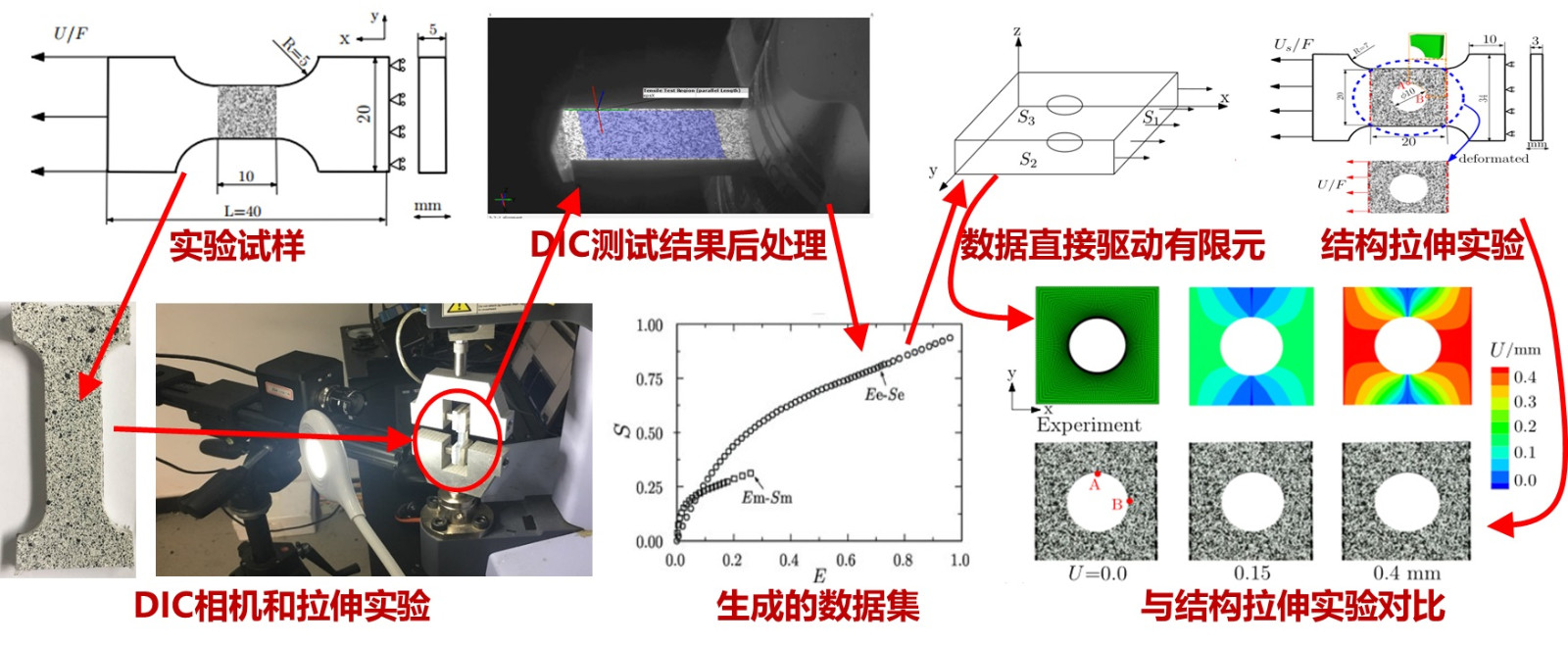

成果一:基于物理机制的数据驱动计算方法

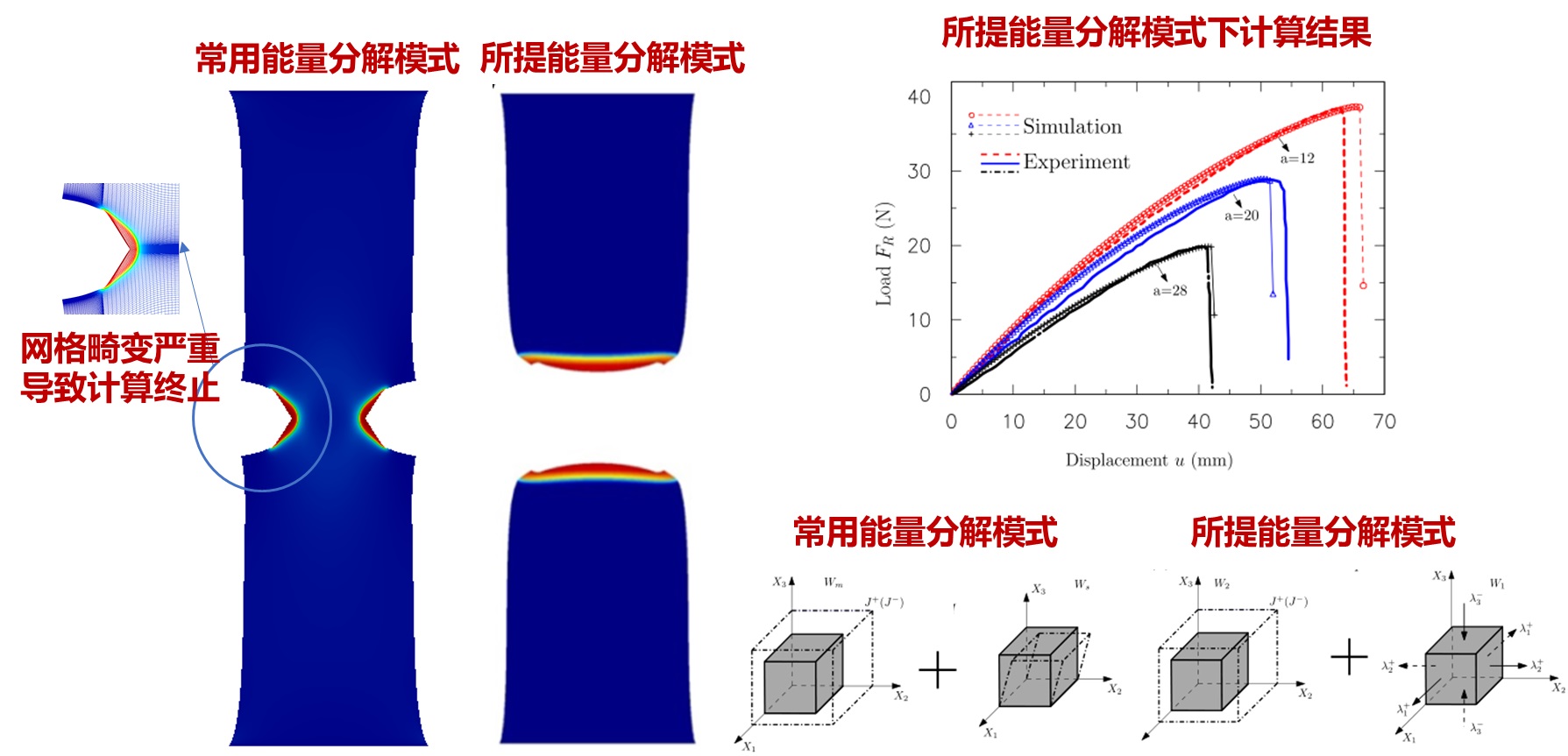

成果二:大变形相场断裂计算方法

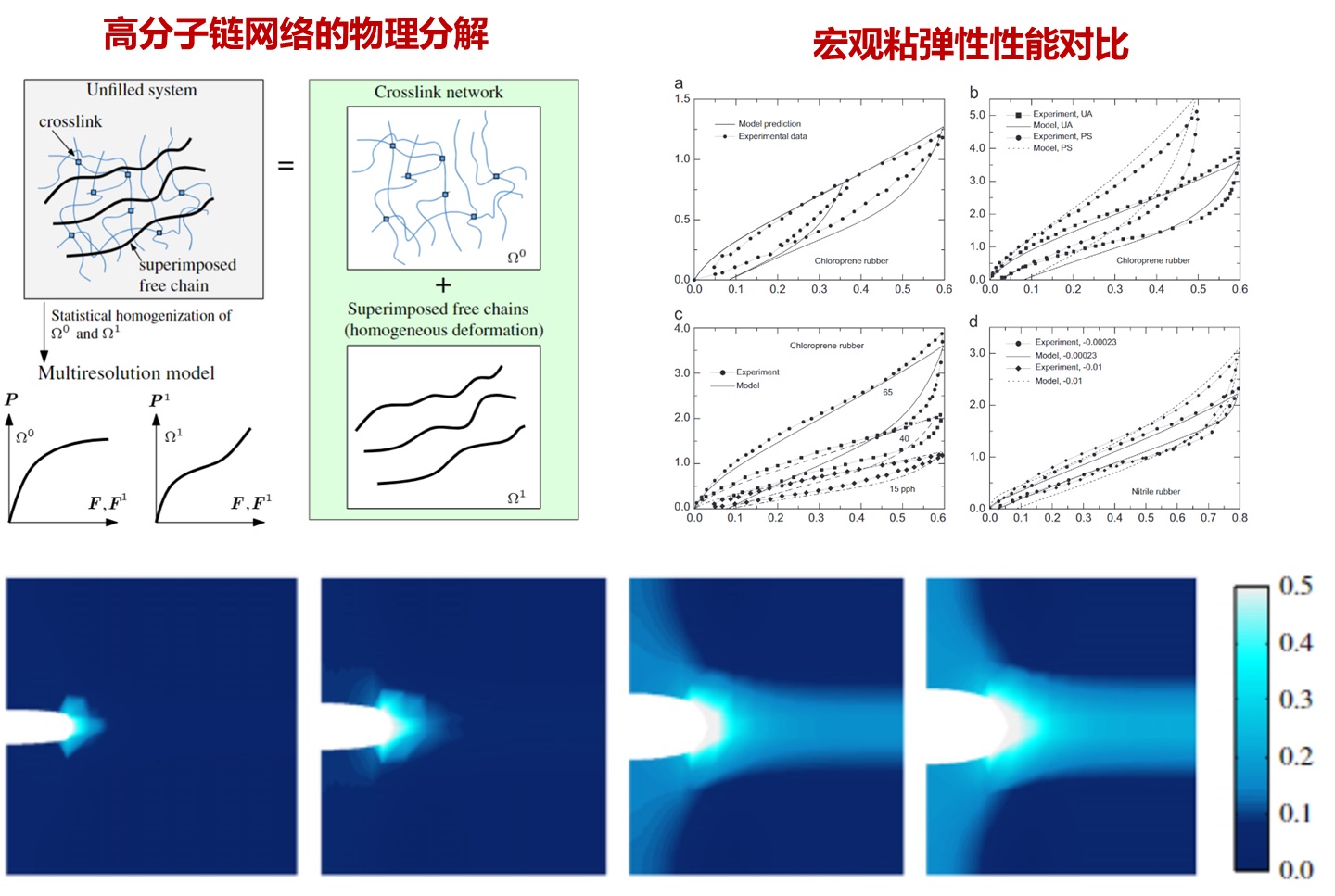

成果三:基于高分子链运动的超弹性和粘弹性力学模型及计算方法

2003.8 -- 2008.10

新加坡国立大学

机械工程

博士

2000.9 -- 2003.7

中科院力学所

固体力学

硕士

1996.9 -- 2000.7

华中科技大学

船舶工程

学士

1993.9 -- 1996.7

重庆大足中学

无

自主CAE软件开发

基于力学机制结合人工智能和数据驱动方法,发展复杂材料建模和结构设计的计算方法

高分子复合材料,金属合金和生物材料(仿生材料)的本构建模

高分子材料(生物材料及仿生材料)的开发制备及跨尺度数值模拟和力学表征

金属材料变形及断裂行为的跨尺度数值模拟及力学表征

先进金属复合材料的开发制备及微观结构表征